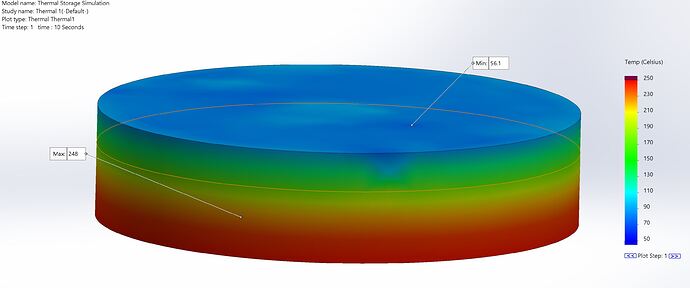

It’s been a while since I posted to this forum but with the new quarter in full swing, I’ve got some updates to share. Last quarter, I focused mostly on analysis and understanding the thermal properties of our ISEC system. This quarter, I am trying to focus more on experimentation, particularly with regards to the solid thermal storage (STS) and pot interface. The STS-Pot interface seems to be a particularly important interface that we need to make sure is conducting heat efficiently; allowing us to cook food rapidly.

To facilitate this, I have been working on procuring and installing STS into my existing ISEC.

Together with the STS mechanical team, we took a foot long section of extruded aluminium 6061 alloy roughly 6.25 inches in diameter and sectioned it into large sections. Roughly 6 and 8kgs respectively. I took the heavier one, which still must be measured precisely, but is roughly 8kg.

To measure the temperature of the ISEC during testing, I decided to install two Type K thermal couples to the STS. Wanting to have a secure connection that is repesentaive of the internal temperature of the ISEC, I opted to drill two holes, approximately 1 inch in depth, into the ISEC.

I then filled the holes with a non-electrically-conductive thermal paste rated for high temperature applications to ensure good thermal contact between the aluminium and the thermocouple. After ensuring the holes were packed full of paste, I inseted the thermocoulples and secured them in place with masking tape temporarily while I worked on mixing some epoxy.

I opted to use JB Weld Steel Cold Solder which is rated for a continuous use temperature of over 500C. Once I applied the epoxy, I let it cure overnight at room temperature.

The next morning I wanted to put the thermal storage to work to make sure that the thermisters were working as expected. It was a cold morning but bright morning with the thermal storage starting at 10C.

In this test, I hooked a 100W solar panel to a classic ISEC pancake heater and placed the 8kg aluminium thermal storage directly on top with no additional modification. This test was meant to be a baseline before I begin making improvements to the design.

I hooked the thermister closest to the pancake heater to channel 0 of the datalogger and hooked the other to channel 1.

I left the ISEC out in the sun for a bit over 2 hours, rotating it periodically to maintain a sun-pointing configuration. I set the datalogger to record data every 30 seconds and at the end of the two hour period, the STS had reached nearly 70C, indicating we were getting roughly 60W of net power into the STS throughout the period.

Over the next few days, I worked on piecing together a python script to handle parsing the data coming from the datalogger and streamlining processing. The python script currently parses the data and produces two sets of plots: temperature versus time and the rate of change in temperature as a function of time. It produces these plots for each channel. Although the test only used two channels, four channels will be used in the near future when I attempt to heat a pot of water.

Below are the results from this test:

From this test I’ve learned the following:

- Both thermocouples report very similar temperatures throughout the entire test because the rate of heating the STS is much slower than the inter-STS heat transfer. In effect, the entire STS heats up at the same rate.

- The connection between the heater and the STS can likely be improved as we were getting around 50% of the power to the STS that we were expecting. Of course, there are other losses such as pointing losses, STS heat losses, and inefficiency of the heater itself (not converting 100% of the input power to heat)

- The datalogger works as expected and I have a repeatable way to produce metrics like the ones above

- More power would make future tests a lot faster and would let me itterate quicker

Overall, a really fun week of testing.

Moving forward I’m going to install a thermal pad at the STS-heater interface to see if it improves the rate at which we heat the ISEC. I’m also going to start experimenting with the STS-Pot interface.